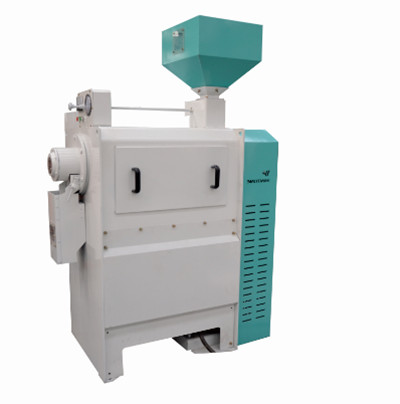

Black Bean Peeling Machine

Black bean peeling machine uses high-speed rotating emery roller to cut and rub the black bean cortex continuously, and the process destroys the bonding strength between black bean endosperm and black bean embryo, which can produce qualified peeled black beans. It has highly efficient air suction chamber inside to collect the bean cortex from peeling process. The bean peeling rate can reach 95% above. Black bean peeling machine is composed of charging device, spiral conveyor, peeling chamber, transmission gear, aggregate bin, discharge device and dust catcher. Black bean peeling machine can work independently as a single machine and also can work in the processing plant which consists of other sections, such as black bean cleaning, destoning, brushing, black bean flour milling and so on.

Black bean peeling machine can remove black bean skin and produce grade peeled black bean kernels. Black bean provides special support for digestive tract health, and particularly our colon. The indigestible fraction (IF) in black beans has recently been shown to be larger than the IF in either lentils or chickpeas. Under many circumstances, we need to peel black bean to improve black beans edible value.

Black bean peeling machine technical parameter:

Model Emery Roll Diameter (mm) Emery Roll Length (mm) Spindle Speed (r/min) Yield (t/h) Power (kW) Air Volume (m³/h) Size (L*W*H) (mm) MTPS-18D/A Φ180 660 1300 1~1.5 22 1370×700×1900 MTPS-18D/B Φ180 660 1300 1~1.5 22 1500-1800 1410×1220×2030 MTPS-25D/A Φ240 660 1050 2-3 30 1515×660×2100 MTPS-25D/B Φ240 660 1050 2-3 30 1800-2100 1515×1220×2100

Workshop Processing for Black Bean Peeling Machine:

Shown at Exhibition Hall:

Our Factory

Workshop

Exhibition

Customer Visit

Our Team

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

- Win Tone will attend the 96th Agricultural and Commercial Show in Zambia

- Global Agents & Distributors Wanted!

- The Statement

- WELCOME TO THE 42ND DAR ES SALAAM INTERNATIONAL TRADE FAIR (DITF)

- Welcome to the 11th Agriculture and Food Exhibition (AGRIFEX- ETHIOPIA)

- Bean Skin Peeling Machine at Argentine Equipment Exhibition

- Welcome to the 123rd Spring Canton Fair 2018

- The Spring Festival Holiday (February 13th—February 22nd) Announcement

- Share Incentive Conference for Zhengzhou Branch of Win Tone Group Was Held Successfully