Chickpea Peeling and Milling Plant

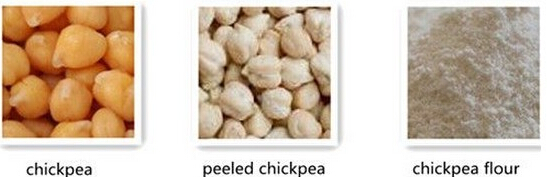

Chickpea introduction:

Chickpeas are popular in many countries, such as India, Australia, Pakistan, Turkey and so on. Chickpeas are rich in iron, folate, phosphorus, protein and dietary fiber. Chickpeas are low in fat and most of this is polyunsaturated. Scientists researched that chickpea consumption may lower blood cholesterol. Therefore, chickpeas and chickpea products have become one of the healthy food in our diet. And it goes without saying that chickpeas processing equipment will also become more and more popular.

Chickpea peeling and milling plant usually includes the following processing steps as below:

1.Bean cleaning section

2. Bean color sorting section

3. Bean peeling section

4. Grading section

5. Bean kernel making and grits milling section

6. Bean flour milling section

7. Measuring and packaging section

The main equipments and functions

1. Vibrating sifter: particle materials cleaning and grading.

2. Bean peeling machine: chickpea peeling.

4. Bean brushing machine: dust, broken pericarp and mud cleaning

5. Bean grinder: chickpea flour milling

6. Electrical measuring and packaging machine

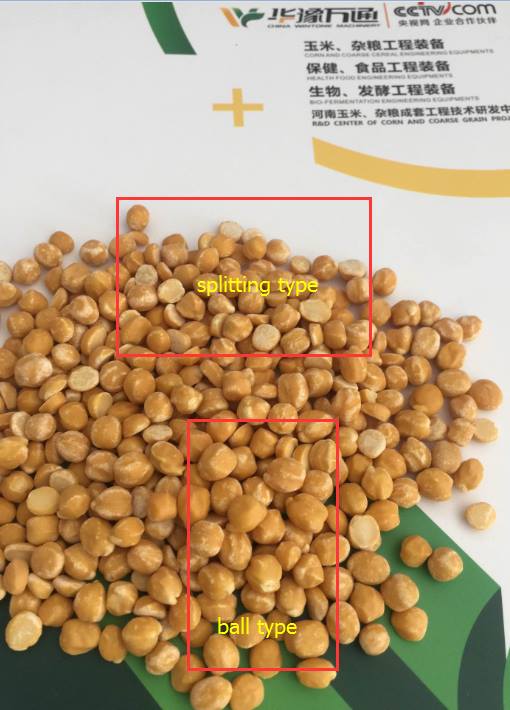

Peeled Chickpea:

Pakistan 20 Sets of Chickpea Peeling Machines Delivery:

Workshop Processing for Chickpea Peeling and Milling Plant:

Shown at Exhibition Hall:

The parameter for the whole chickpea peeling and flour milling processing plant:

|

Type

|

Power (kw)

|

Power Consumption(kw/h)

|

Capacity(t/24h)

|

Workshop Dimension(l*w*h/m)

|

|

10t

|

24

|

38-40

|

10

|

10*4*4 (steel structure)

|

|

20t

|

56

|

38-40

|

20

|

16*5*5 (steel structure)

|

|

30t

|

72

|

38-40

|

30

|

20*5*5 (steel structure)

|

|

50t

|

119

|

38-40

|

50

|

20*5*7 (steel structure)

|

|

100t

|

238

|

38-40

|

100

|

30*5*7 (steel structure)

|

Our Factory

Workshop

Exhibition

Customer Visit

Our Team

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

- Win Tone will attend the 96th Agricultural and Commercial Show in Zambia

- Global Agents & Distributors Wanted!

- The Statement

- WELCOME TO THE 42ND DAR ES SALAAM INTERNATIONAL TRADE FAIR (DITF)

- Welcome to the 11th Agriculture and Food Exhibition (AGRIFEX- ETHIOPIA)

- Bean Skin Peeling Machine at Argentine Equipment Exhibition

- Welcome to the 123rd Spring Canton Fair 2018

- The Spring Festival Holiday (February 13th—February 22nd) Announcement

- Share Incentive Conference for Zhengzhou Branch of Win Tone Group Was Held Successfully