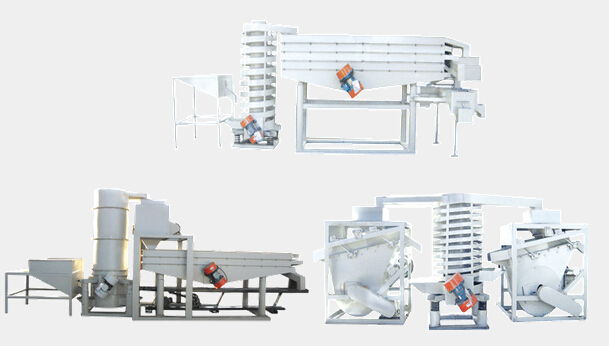

Hazelnuts Dehusker

[Functions and Features]

The hazelnuts dehusker provides one-stop solution for food industry. It can grade nuts, dehull and separate shells. The machine can be also used to process almond.

[Component]

The hazelnuts dehusker consists of:

Grading/sizing machine, 1set

Dehulling and separating machine: 1set

Shells separator: 1 set

Electric control cabinet: 1 set

Grading/sizing machine consists of input hopper, elevator and sizing machine. It is used for grading/sizing inshell almonds into 4 grades.

The hazelnuts dehusker consists of input hopper, elevator, dehuller, separating screen, elevator for un-hulled almond, laminated-spring conveying sieve for unhulled almond. It can dehull almond nuts after grading, then separate out the small shells and unhulled almonds from kernels, through which the mixture of shells and almond kernels will eject into the collecting bin.

Shells separator consist of input hopper, elevator and two separators. It is used to sort out shells from hazelnuts kernels.

[Technical parameters]

Power:9.08kw (380v 3phase 50Hz)

Input capacity:500kgs/hour

% of whole kernels: 98% min.

% of kernels in shells: 0.3%

% of shells in kernels: 2% max.

Space occupied: 18.5m×1.6m

Height:1.7m

Weight: 3.0mts

Our Factory

Workshop

Exhibition

Customer Visit

Our Team

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

- Win Tone will attend the 96th Agricultural and Commercial Show in Zambia

- Global Agents & Distributors Wanted!

- The Statement

- WELCOME TO THE 42ND DAR ES SALAAM INTERNATIONAL TRADE FAIR (DITF)

- Welcome to the 11th Agriculture and Food Exhibition (AGRIFEX- ETHIOPIA)

- Bean Skin Peeling Machine at Argentine Equipment Exhibition

- Welcome to the 123rd Spring Canton Fair 2018

- The Spring Festival Holiday (February 13th—February 22nd) Announcement

- Share Incentive Conference for Zhengzhou Branch of Win Tone Group Was Held Successfully