CTNM15B Complete Rice Milling Machine

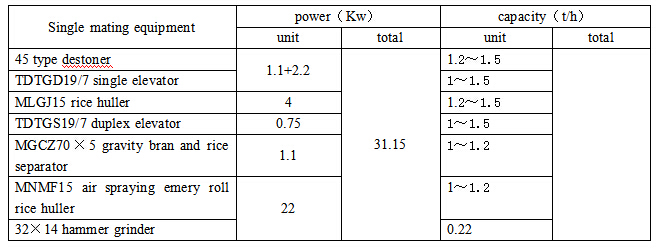

Main mating equipment for CTNM15B complete rice milling machine: 45 type destoner, MLGJ15 rice huller, MGCZ70×5 gravity bran and rice separator, MNMF15air spraying emery roll rice grinder. The rice milling machine is in compact structure, easy to operate and maintain, large yield and highly precise, widely used in the farm, town, and rice processing workshop. It can increase the milling precision by adding following equipment according to client’s requirement. See indexes of the main mating equipment.

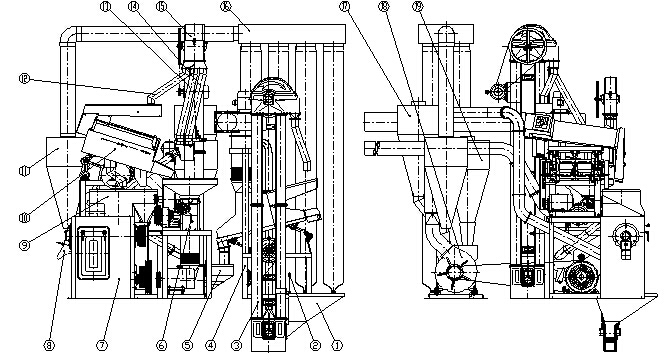

1. Charging hopper 2. Hopper gate3. Single elevator 4. destoner 5. Double chain bucket 6. Rice huller 7. Rice grinder 8. Rice outlet

9. Brown rice hopper 10.gravity bran and rice separator 11.bran cyclone 12. Gravity charging tube 13. Double sieve tube 14. Double hulling tube

15. Duplex elevator 16.cloth deduster 17.fine bran cyclone 18. Wind blower type hammer grinder 19. crude bran cyclone

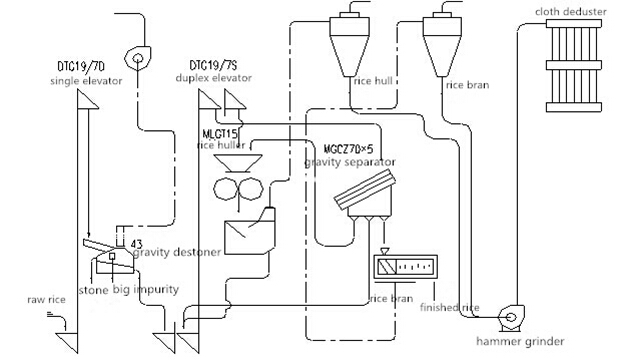

CTNM15B type rice milling machine processing flow

The raw rice is poured into charging hopper and then elevated to cleaning screen by the single elevator. The rice without big impurities is sent to destoner to remove impurities heavier than the rice and a part of light impurities and dust. The clean rice is conveyed to rubber covered roller hulling machine by the duplex elevator to be hulled. The big husks are separated out and conveyed out of the machine or collected by the cyclone and sent to the grinder; the mixture is conveyed by duplex elevator to the gravity separator which separates out three materials. Those with most unhulled rice is flowed back through the tube to the duplex elevator which conveys the materials to the rice huller; the bran and rice mixture is conveyed by the duplex elevator to the gravity separator again; the pure rice is directly sent to the brown rice bucket and goes into the rice milling machine. The fine husks in milling chamber are collected by cyclone through the wind blower and sent to the grinder to be ground into finished rice and discharged through the outlet.

Besides, the brown rice hopper and the duplex elevator are equipped with switch gate which, at the beginning of the processing, guarantees enough time for the rice completely spread on the the sieve cover which adjusts to the ideal distribution effect to make sure pure rice to the milling chamber; at the end, makes all the materials to the huller and directly to the milling chamber so as to fast put an end to the processing. The whole equipment has no residual materials.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Our Factory

Cases

Exhibition

Customer Visit:

Sales Team

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

- Win Tone will attend the 96th Agricultural and Commercial Show in Zambia

- Global Agents & Distributors Wanted!

- The Statement

- WELCOME TO THE 42ND DAR ES SALAAM INTERNATIONAL TRADE FAIR (DITF)

- Welcome to the 11th Agriculture and Food Exhibition (AGRIFEX- ETHIOPIA)

- Bean Skin Peeling Machine at Argentine Equipment Exhibition

- Welcome to the 123rd Spring Canton Fair 2018

- The Spring Festival Holiday (February 13th—February 22nd) Announcement

- Share Incentive Conference for Zhengzhou Branch of Win Tone Group Was Held Successfully