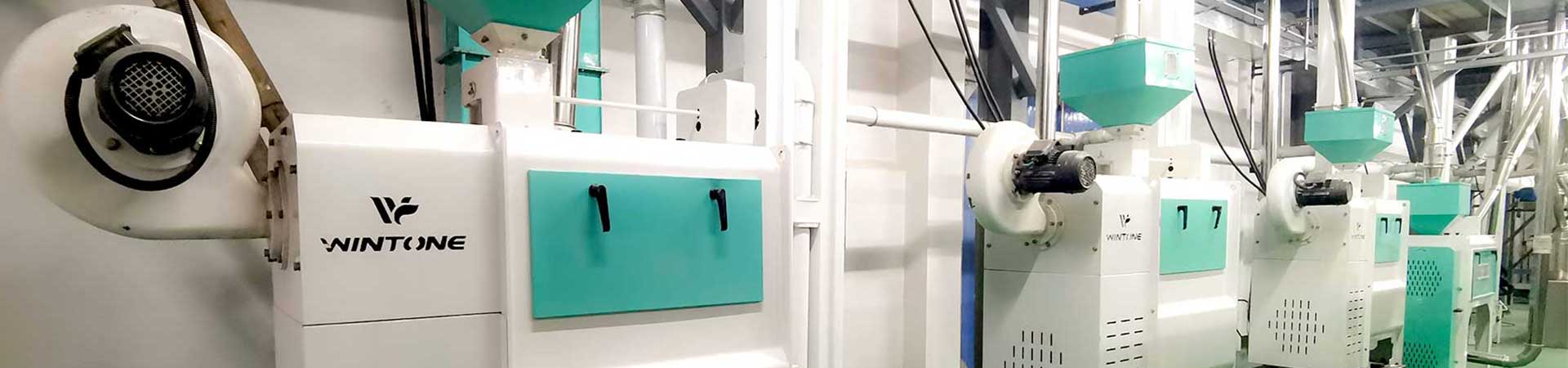

China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

In oat processing, oats peeling and remove the tat equipment is critical. Oatmeal goes through an oat hulling machine and becomes naked oat after it has been removed from the surface. Naked oats after cleaning, peeling, remove the wheat and other surface attachments of harmful substances, to become high-quality oats. WinTone Machinery's HTP Series Oat Huller is a specialized oat huller for oat processing enterprises, capable of hulling Russian oats, Australian oats, Canadian oats, and domestic naked oats. The oat huller can be adapted to large, medium, and small oat processing production lines.

HTP Oat Huller Working Principle

The HTP oat huller is a centrifugal oat hulling equipment that mainly uses blades to throw oat grains through a high-speed rotating centrifugal plate. There are guide grooves on the centrifuge plate to keep the grains in a fixed direction and collide with the surrounding rings, breaking the cereal grains into multiple parts and separating them to complete the hulling process.

HTP Oat Huller Performance Advantages

1. Variable speed to adjust the impact hulling speed, adapt to different varieties of oats hulling;

2. Oats were shelled uniformly by centrifugal guidance, with high shelled rate at one time and little broken oats;

3. Low energy consumption for equipment operation, stable continuous operation of production line;

4. PLC control system, frequency conversion speed regulation, human-machine interface intelligent control system,easy to adjust.

HTP Oat Huller Finished Product

HTP Oat Huller Technical Index

Type

Capacity(t/h)

Power(kw)

Dimension(mm)

HTP-60

0.5-0.8

3

1029×788×710

HTP-80

3-4

7.5

1253×1253×1928