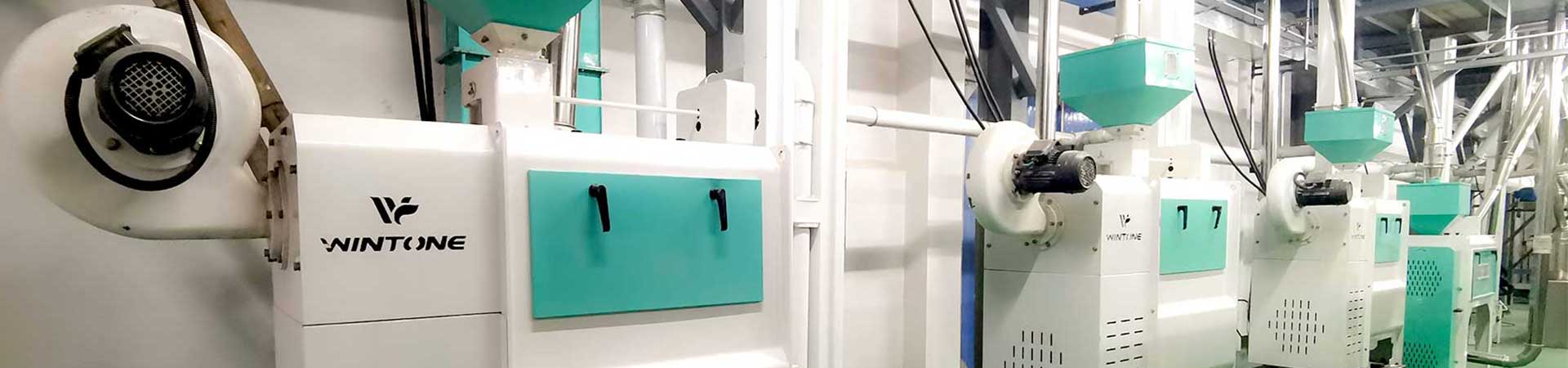

China WinTone

Grain Peeling Machinery

Internationally Certified Equipment, Customized Solutions, Suitable for Multiple Processing Scenarios including Wheat, Corn, Soybeans, and More.

-

Industrial Park, Lushan, Henan, China

-

WhatsApp: +86 19937392058

-

Mail Support:wintone16@wintonemachinery.com

-

Response Time: Within 24 Hours

Comments

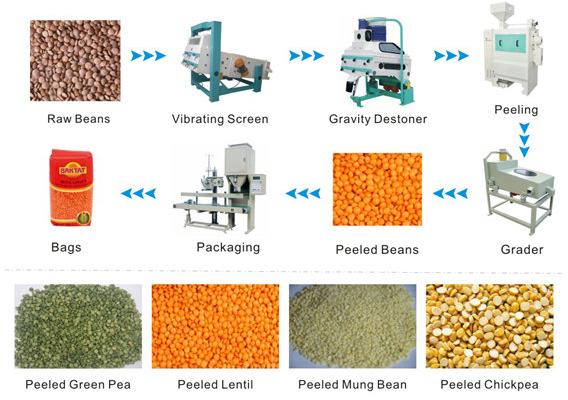

Red Lentil Cleaning and Dehulling Line

The Red Lentil Cleaning and Dehulling Line mainly includes cleaning and hulling processes:

Lentil Cleaning Line Process: once sifting, destoning and magnetic separation. Materials are conveyed by elevator, medium pressure aspiration system is used to remove the dust. Feature: The raw material contains impurities, which seriously affects hulling process of lentils. Hence, we design a process of sifting and destoning. The highly efficient vibration sifter is used to remove big and small impurities as well as the light dust with vertical air suction tunnel. Then the destoner is used to clean out heavier impurities like stones as well as dust with medium pressure aspirator which can effectively reduce black spots in the lentil. The magnetic drum is used to remove iron in the material.

Lentil Hulling Machine Feature: The advanced hulling technology is composed of extraction, hulling, brushing, adding oil, air cooling, grading and packaging. The extractor effectively removes worm damaged, mildewed and broken particles, increasing quality of the lentil. The hulling process includes 3 times of light grinding. The brusher effectively removes dust on the surface of the material. The double-case plansifter is used to separate brokens in the lentil.

Technical Parameter:

Project Model

Power(kw)

Power Consumption(kw/h)

Capacity(t/24h)

Workshop Dimension(l*w*h/m)

10t

24

38-40

10

10*4*4 (steel structure)

20t

56

38-40

20

16*5*5 (steel structure)

30t

72

38-40

30

20*5*5 (steel structure)

50t

119

38-40

50

20*5*7 (steel structure)

100t

238

38-40

100

30*5*7 (steel structure)