Lupin Dehulling Machine

Lupin Dehulling Machine has the air draft dedusting system, which ensures the best sanitation condition. YTPS-25B Lupin Dehulling Machine connects with highly efficient air indraft system, which ensures reliability of bean bran discharging. It has strong cooling system so as to ensure high sanitation standard.

Lupin Dehulling Machine has the features of easy operation and maintenance. Its sieve plate and other accessories are quick-replaceable. It has durable emery roll and less wearing parts. This feature makes Lupin Beans Peeling Machine easily operated and maintained.

Lupin Dehulling Machinee also has uniform end products and reliable quality. There are different adjustment choices for you even in the peeling process, for example, you can adjust feeding speed and outlet pressure to increase the friction and pressure in the peeling chamber so as to produce high quality end products.

Lupin Dehulling Machine has moderate peeling process and high processing efficiency. Stable bean flow and the efficient air indraft system inside of the machine makes the peeling process moderate so as to reduce bean loss in processing and ensures the profit maximization.

unhulled lupin

dehulled lupin

Application area of Lupin Dehulling Machine:

Lupin Dehulling Machine is used in the peeling and germ removing section in bean processing industry, and the preliminary cleaning section of breweries and feed enterprises.

Working principle of Lupin Dehulling Machine:

The material is sent by the screw propeller to the center part of the Lupin Dehulling Machine- the peeling chamber. Then it utilizes emery roll that rotates with high speed to cut and rub the bean bran continuously and make bean bran separated. Then the material is conveyed to the discharging port and the peeling process is finished.

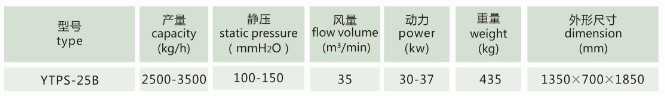

Technical parameter of lupin dehulling machine:

Workshop Processing for Lupin Dehulling Machine:

Shown at Exhibition Hall:

Our Factory

Workshop

Exhibition

Customer Visit

Our Team

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

- Win Tone will attend the 96th Agricultural and Commercial Show in Zambia

- Global Agents & Distributors Wanted!

- The Statement

- WELCOME TO THE 42ND DAR ES SALAAM INTERNATIONAL TRADE FAIR (DITF)

- Welcome to the 11th Agriculture and Food Exhibition (AGRIFEX- ETHIOPIA)

- Bean Skin Peeling Machine at Argentine Equipment Exhibition

- Welcome to the 123rd Spring Canton Fair 2018

- The Spring Festival Holiday (February 13th—February 22nd) Announcement

- Share Incentive Conference for Zhengzhou Branch of Win Tone Group Was Held Successfully